When he’s not teaching remote-learning classes, Rob Barndollar is helping his son, Ben, make 3D printed components for face shields — and assembling them.

While he’s experienced …

This item is available in full to subscribers.

We have recently launched a new and improved website. To continue reading, you will need to either log into your subscriber account, or purchase a new subscription.

If you are a current print subscriber, you can set up a free website account by clicking here.

Otherwise, click here to view your options for subscribing.

Please log in to continue |

|

When he’s not teaching remote-learning classes, Rob Barndollar is helping his son, Ben, make 3D printed components for face shields — and assembling them.

While he’s experienced an apparent shortage recently of elastic, Barndollar said his son printed himself a cutting tool which trims automobile rubber components which they’ve been using to secure the shields.

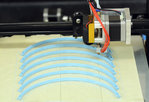

“He gets his smarts from his mother, I can assure you,” said Barndollar this past Thursday from his industrial arts classroom at Owensville High School. Several 3D printers were in action creating the head bands with raised nobs to accept a punched piece of clear, medium weight plastic sheeting material.

Several hundred were finished. Several hundred more awaited final installation of the sheeting material. Joe Barndollar, a 2008 OHS graduate, is a chemist and senior process engineer for Henniges Automotive in New Haven took a commonly produced face shield and modified the design.

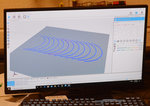

He made 12 revisions to a readily produced mask which eliminated a gap between the wearer’s forehead and the shield. His “Show Me Face Shield,” redesign incorporates a comb ring binder for securing reports and booklets which allows for the use of everyday plastic report covers for the shield.

In a blog post published about his program, Barndollar said the cost per face shield is about 60 cents.

He can produce about 150 of the shields per day. His father is running several 3D printers at the school to help in the process. Rod Barndollar said the shortage of elastic in the area prompted his son to come up with way to trim some rubber stripping material into thinner strips which they could substitute for the band to secure the shields.

The finished shields have been given to area emergency workers, firemen, police, and hospital and nursing home health care providers.